About Opanpan

As a manufacturer, Linyi Oupanpan Door Industry Co., Ltd.(short for Opanpan) specializes in the R&D and production of decorative door skins, wall panels, molding lines and finished doors. The main type of decorative door skins is density board veneer melamine paper. It derives various decoration styles through molding , carving ,inlaying etc. processes. At the same time, Opanpan produces wall panels and molding lines in the same color as the door skin. It enables decoration service providers who cooperate with Opanpan to provide their customers with more design-oriented service solutions.

With the fact that finished door filling materials,such as brigde structure particleboard,graphene,honeycomb papaer ,are all under Opanpan Self-operated R&D and production, it prompts Opanpan master the core technologies in interior door key indicators as quietness, fire resistance and waterproofness etc.Opanpan is located in Linyi, China, which is known as the world’s board capital. Opanpan currently directly operates two production bases, one logistics storage center and an exhibition hall. The first production base is located at Cross of Industrial 2 road and Shengya Road and mainly produces decorative door skins, wall panels,molding lines and honeycomb paper.

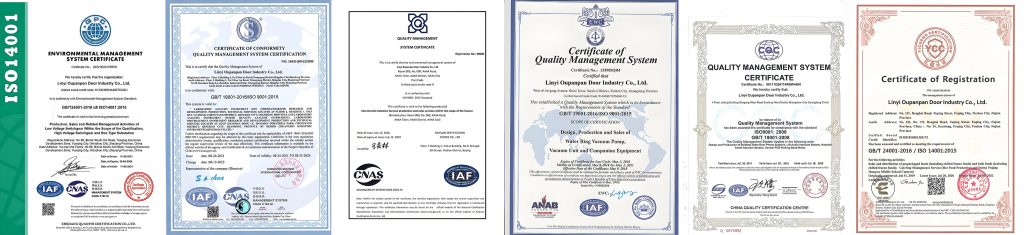

Qualifications and certificates

Production site

The production base covers an area of 45,000 square meters and has a variety of production equipment and processes, such as hot pressing production lines, carving production lines, and gluing production lines. The daily output of decorative door skins can reach 80,000 square meters. The second production base is located at No.8 of Dacheng Village road. It mainly produces finished wooden doors, door frames, etc. It has production equipment such as pressing, trimming, and edge sealing. The daily output of ordinary wooden doors can reach 2,000 pieces. The logistics and warehousing center is located at Cross of Xicheng road and Guangming Road and the exhibition hall is located at 102 Hall of C20 area, Huaqiang Decoration Market.

The Zenith extreme heat treatment medium density fiberboard production line made in Germany can better make the surface film and the base board fit together, and the process is environmentally friendly and meets EU requirements. The board processing surface is flat and consistent, the cooling time is reduced, the service life is long, and it is convenient for subsequent processing.

Oupanpan uses advanced fully automatic PLC hexagonal saw production technology to ensure the accuracy of the size of the board and door panels. The cut surface is flat, which is conducive to the next step of the hemming process. The four edges are guaranteed to be parallel and vertical, which increases the rate of finished door panels.

Opanpan Direct-operated storage center

Taking advantage of Linyi as the logistics capital, Oupanpan’s self-operated logistics center can quickly and safely deliver logistics to distributors across the country. Thanks to the location advantage of Qingdao Port, the largest port in Asia, Oupanpan can meet the shipping needs of global door industry buyers.

Door panel Deep Processing

Door panels can be processed through punching, inlaying, glass configuration, hardware and other subsequent processes according to different customer requirements. Opanpan continues to update and iterate the design style of door panels to meet the requirements of customers from different countries and regions with different cultural backgrounds.

For many years Opapan has providing raw material matching and R&D service support for many well-known interior door brands in China. At the same time, Opanpan decorative door skins, wall panels, molding lines and finished wooden doors have been exported overseas through domestic Chinese traders and overseas clients.

Production Strength

Opanpan is located in Linyi, the world’s capital of panels. It can provide high-quality and low-cost products to customers .

Advanced Equipment

Opanpan wooden door production line uses equipment produced in Germany. It has explored reliable production technologies.

Continuous innovation

Opanpan keeps a close eye on the international market, to meet the customers from different cultural backgrounds.

Safety performance

We realize that the door is part of the home, so from the beginning, we always put the safety of the product in an important position.

Professional R&D

Opanpan research and development is not limited to the style and appearance, but also goes deep into the field of raw materials.

Eeo- protection concept

We implement eco-protection concepts in raw material procuremen. We advocate the protection of scarce forest resources.

5-year warranty

We solemnly promise that within 5 years from the date of delivery of the product through reasonable channels and initiate a claim.

Worldwide delivery

Opanpan is only 3-hour drive from Qingdao Port. We can deliver the goods you need to you with the best transportation solution.

In the future, Opanpan will be willing and strive to exchange development concepts and establish cooperative relationships with partners in the door industry around the world to achieve common prosperity and progress.

Opanpan Door Skins

Opanpan Door Skins