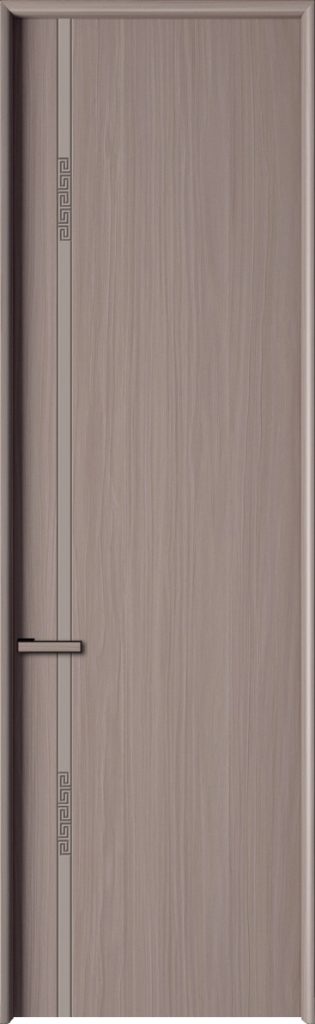

Excimer natural diatom mud wooden door

The excimer natural diatom mud wooden door is a classic style among Opanpan’s MDF wooden doors. Due to the extensive use of environmentally friendly materials and the implementation of the integrated door, wall and cabinet design concept, the excimer series of wooden doors are widely loved by users all over the world.

Section 1: Materials of Door Skins

The MDF door skin with excimer natural diatom mud added has unique physical properties. In addition to being easy to process and having good strength in structure, it also performs well in the field of environmental protection.

| Natural and environmentally friendly | Diatom mud is mainly composed of siliceous sedimentary rocks of biological origin, which is low-carbon and environmentally friendly and does not contain harmful additives. |

| Air purification | The porous structure of diatom mud has the functions of adsorbing formaldehyde, eliminating odors, releasing negative oxygen ions,and purifying the air. |

| Humidity regulation | Diatom mud can autonomously adjust the indoor air humidity to achieve relative balance, prevent frost, reduce mold and static electricity. |

| Sound absorption and noise reduction | Giving diatom mud molecules a porous structure can effectively absorb noise and greatly reduce the harm of noise to the human body. |

| Fire retardant | Diatom mud is composed of inorganic materials, so it does not burn. Even if a fire occurs, it will not produce harmful gases to the human body. |

| Durable | The surface is not powdery, cracked, warped, peeled, or damaged by humans. Diatom mud can be used for at least 20 years. |

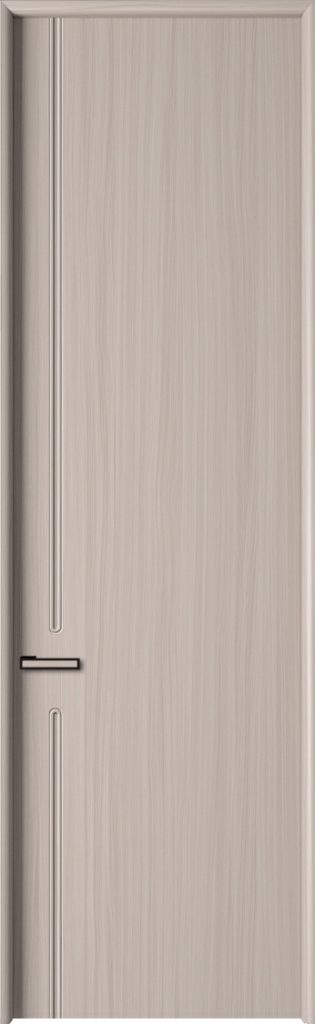

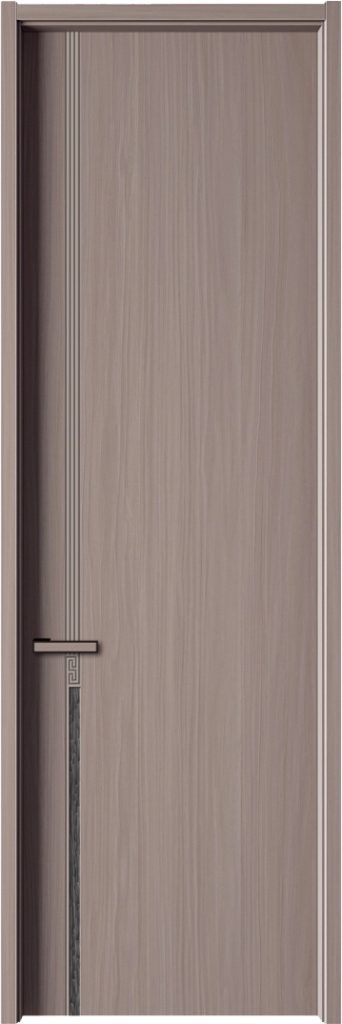

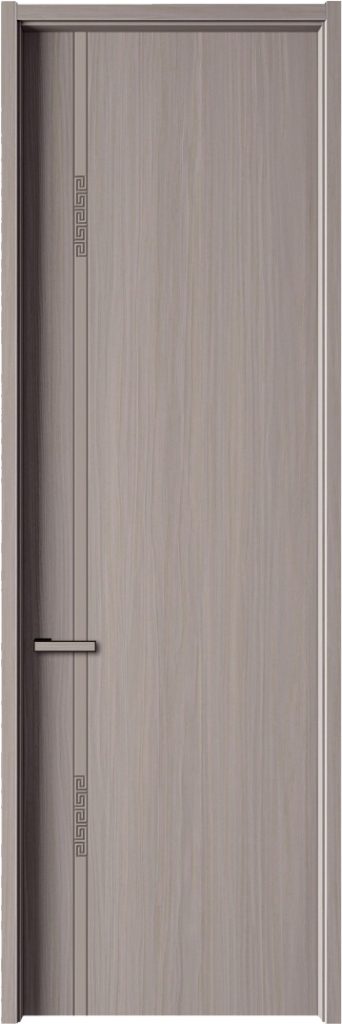

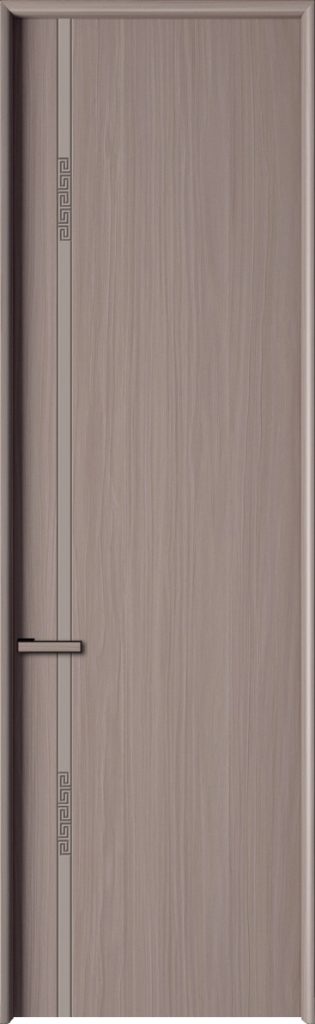

| JL-601-BS | JL-602-SDY | JL-603-CL | JL-605-FR |

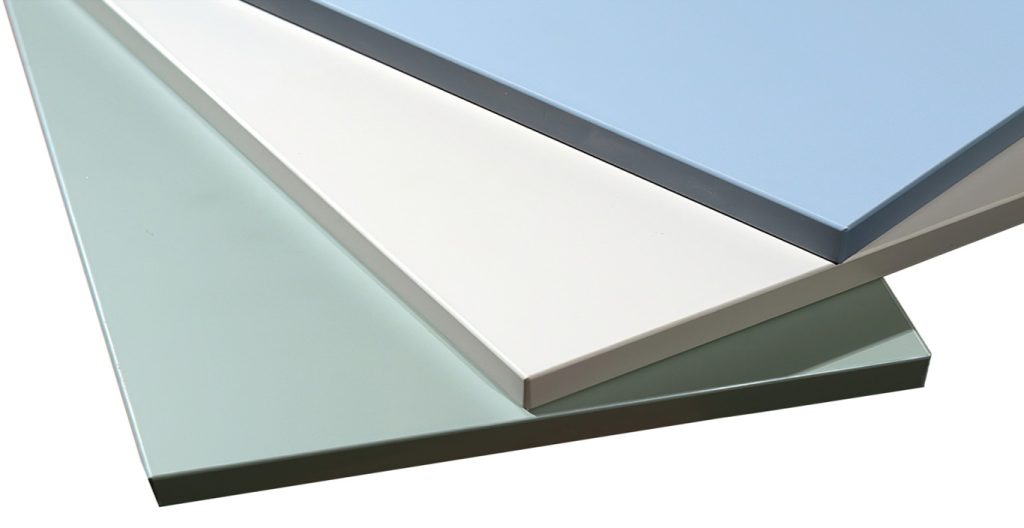

- Melamine Paper

- Excimer natural diatom mud MDF

The melamine paper is formed by three layers as:Top paper is the outermost protective layer, which makes the door skin hard,wear-resistant and highly transparent. Decorative paper is located under the top paper, which plays a decorative role and has good hiding power, impregnation and printing properties. Bottom paper is made of phenolic resin glue as a mechanical support to provide structural stability for the door skin.

Sapphire blue oriental charming MDF as the base material of the door skin. Diatom mud products have a unique molecular sieve structure, with extremely strong physical adsorption and ion exchange functions, which can release negative oxygen ions,effectively absorb free formaldehyde, benzene, ammonia and other harmful substances in the air, as well as odors caused by pets,smoking, and garbage, and purify indoor air.

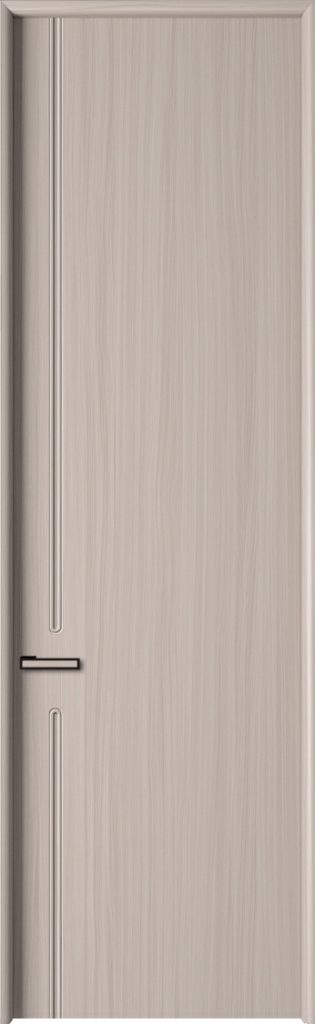

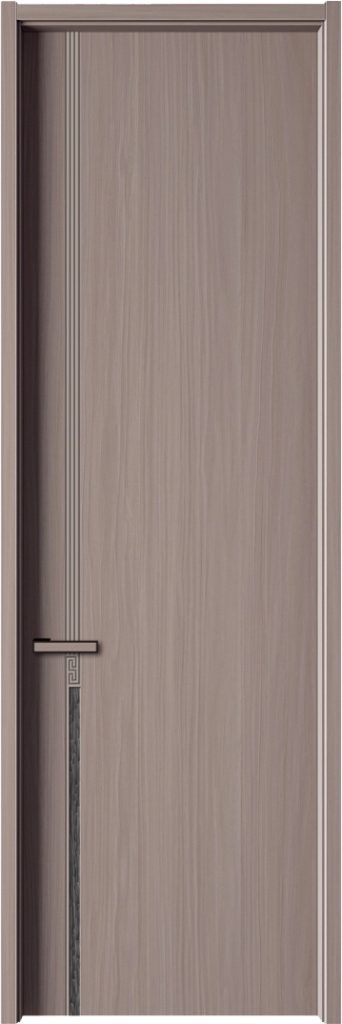

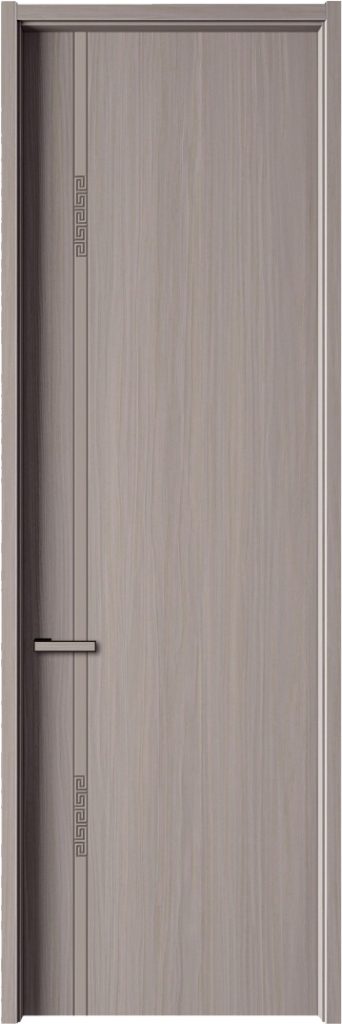

Section 2: Contemporary minimalist design of composite wooden doors

Within the maximum size limit, customers can freely customize the size of the door.Within simultaneous molding、carving and inlaying etc. processes, the door skins derives various designings and all of them can be customized according to customer requirements.

| Max size of customization | 2250×950mm |

| Thickness of door leaf | 45mm or Customization |

| JL-606-SM-1 | JL-607-SM-2 | JL-608-SM-1 | JL-608-SM-2 |

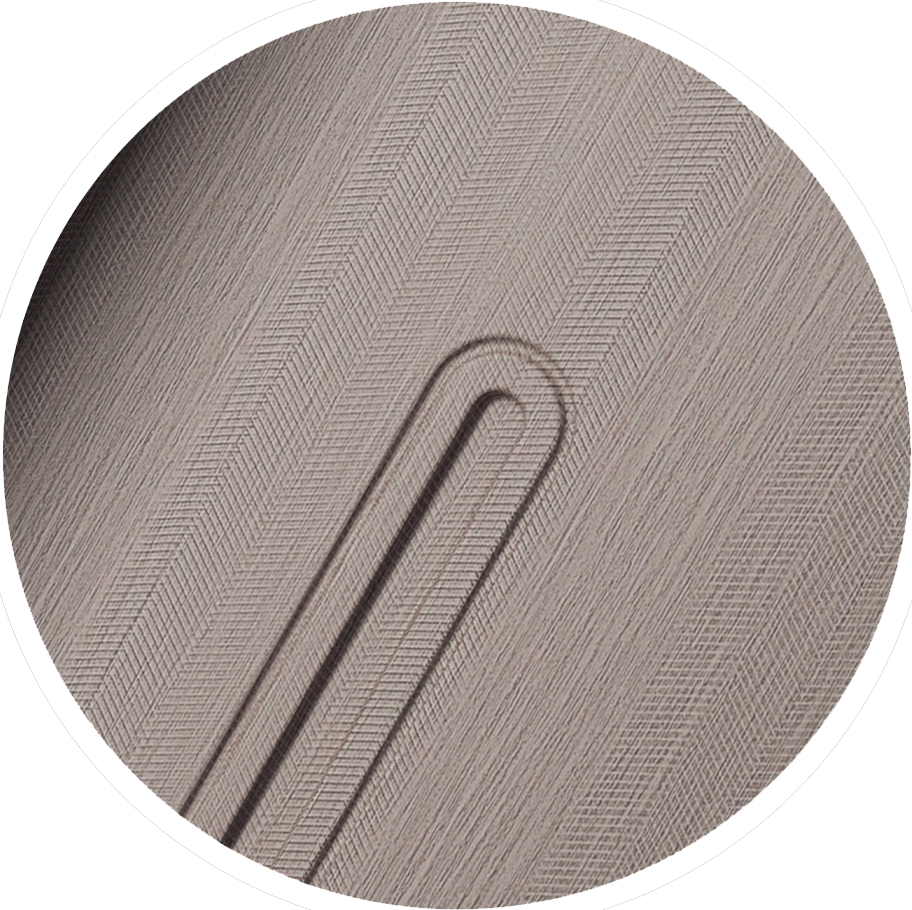

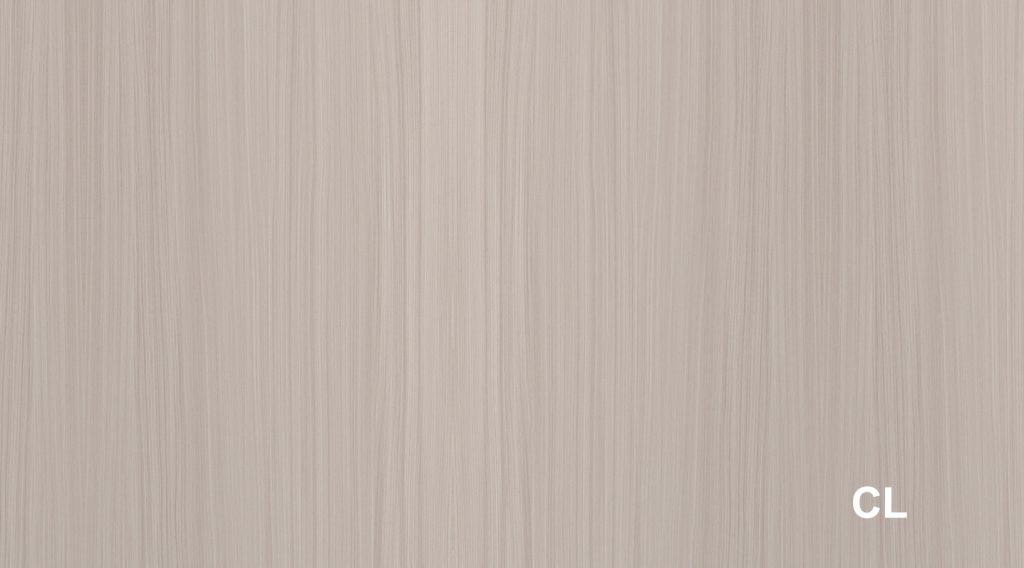

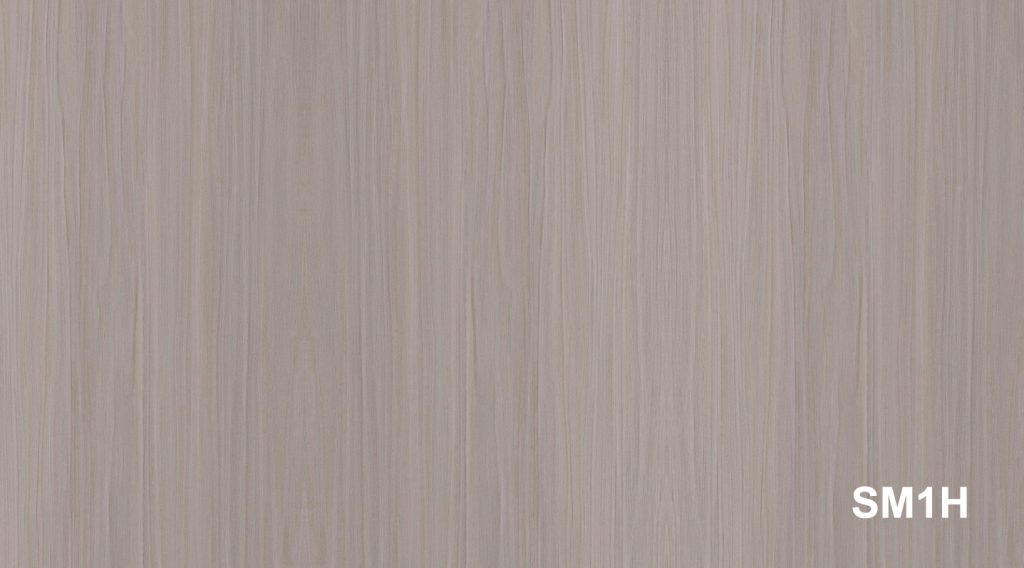

Section 4: Colour of surface

Door panel design is produced by the pattern of melamine paper, combined with molding, carving and inlaying etc. processes. The common patterns of melamine paper are as follows, and it can also be customized according to customer requirements.

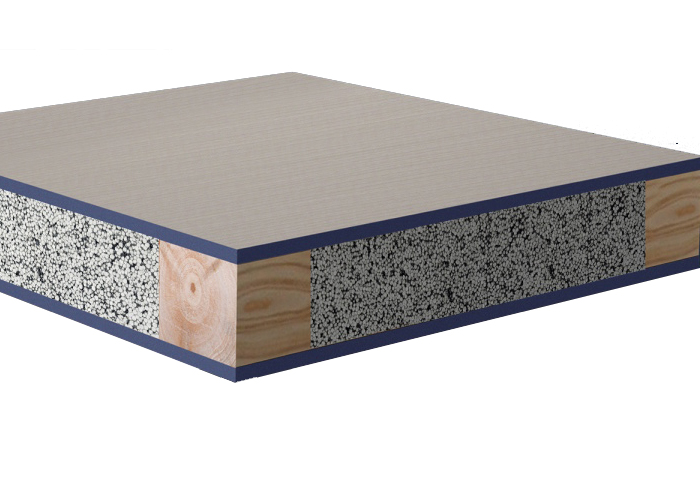

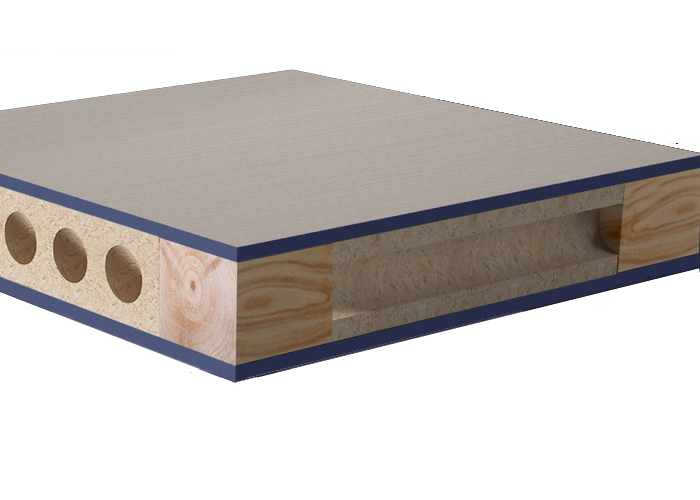

Section 5: Filling Materials of door

The filling materials in the door panels are mainly composed of solid wood, bridge hole boards, MDF, honeycomb paper and graphene,which can be mixed and matched. The above materials have different performances in terms of door panel strength, sound insulationand weight. Customers can customize according to their actual needs.

| Graphene | 3D Silent Mechanical Board | Bridge Hole Knot Board |

| Graphene has high strength, hardness and certain toughness, which can effectively prevent door panel deformation. It also has thermal conductivity and flame retardancy, which can improve the thermal insulation effect of door panels and enhance the fire resistance level. The honeycomb structure of graphene helps to reduce noise. Moreover, it is environmentally friendly and non-toxic, which meets the environmental protection requirements of modern homes. |

The three-dimensional silent mechanical board has excellent bending strength and bearing capacity, keeping the door leaf from deforming. Compared with traditional materials, the three-dimensional silent echanical board is lighter, which helps to lower the overall center of gravity of the door body, improve stability and movement speed. The structure of the three-dimensional silent mechanical board helps to improve the sound insulation effect of the door and provide a comfortable indoor environment for residents. | The bridge hole knot board has good waterproof performance, and effectively prevents temperature from overflowing, and has good thermal insulation effect. The bridge hole knot board is thicker, and the sound insulation effect can reach 33 decibels. Thebridge hole board door meets the E1 environmental protection standard, and the free formaldehyde emission is low, which isharmless to the human body. The internal force of the bridge hole knot board is uniform, not easy to deform, and it can remain stable even in a humid environment. |

Section 6 :Door finished

| CONSTRUCTION | |

| General | Sandwich construction, softwood inner skeletons laminated with MDF |

| Species | Oak, Ash, Sapele, Walnut, Teak, Cherry, Maple etc. available |

| Size | Standard thickness as 35mm, 40mm or 45mm, customized size available |

| SKIN SPECIFICATION | |

| Melamine Paper | 0.6mm veneer quarter / crown cut |

| MDF | 5mm MDF or 8mm MDF E1 |

| Edge band | 0.6mm veneer edge band or solid wood edge available |

| INNER SKELETON AND CORE | |

| Skeleton | Finger-joint softwood or LVL |

| Fill-in core | Honycomb paper\tubular particle board\solid wood core\3D silent mechanical board\Graphene |

| Painting option | No painting required |

| JL-601-BS | JL-602-SDY | JL-603-CL | JL-605-FR |

| JL-606-SM-1 | JL-607-SM-2 | JL-608-SM-1 | JL-608-SM-2 |

Section 7:Decoration scene

After the decorative panels and fillers are bonded, molded, cut, and edge-sealed, a relatively complete door leaf is formed. The door leaf has many excellent properties, such as environmentally friendly, formaldehyde-free, waterproof, soundproof, and scratch-resistant. Customers can freely customize various door locks and hinges installation on the completed door leaf.

- Conventionally, 5mm or 8mm MDF veneer as decoration door skin panel, and various shapes can be customized and carved.

- The four sides of the door leaf, the lock location and the internal frame structure are all made of multi-layer solid wood,which provides a thick and stable solid wood feel.

- Double-sided non-painting process, environmentally friendly, waterproof and wear-resistant.

- Various designs are available, which can be adapted to various architectural styles of different regions and cultures.

- The internal filling can be freely selected from solid wood square, bridge hole board, honeycomb paper, and graphene etc., with excellent noise reduction effect.

Section 8: About Opanpan

As a manufacturer, Linyi Oupanpan Door Industry Co., Ltd.(short for Opanpan) specializes in the R&D and production of decorative door skins, wall panels, molding lines and finished doors. The main type of decorative door skins is density board veneer melamine paper. It derives various decoration styles through molding , carving ,inlaying etc. processes.

At the same time, Opanpan produces wall panels and molding lines in the same color as the door skin. It enables decoration service providers who cooperate with Opanpan to provide their customers with more design-oriented service solutions. With the fact that finished door filling materials,such as brigde structure particleboard,graphene,honeycomb papaer ,are all under Opanpan Self-operated R&D and production, it prompts Opanpan master the core technologies in interior door key indicators as quietness, fire resistance and waterproofness etc.

- Qualifications and certificates

Opanpan Door Skins

Opanpan Door Skins