OPANPAN Carbon Fiber MDF Door Skin DFL-30P Series Introduction

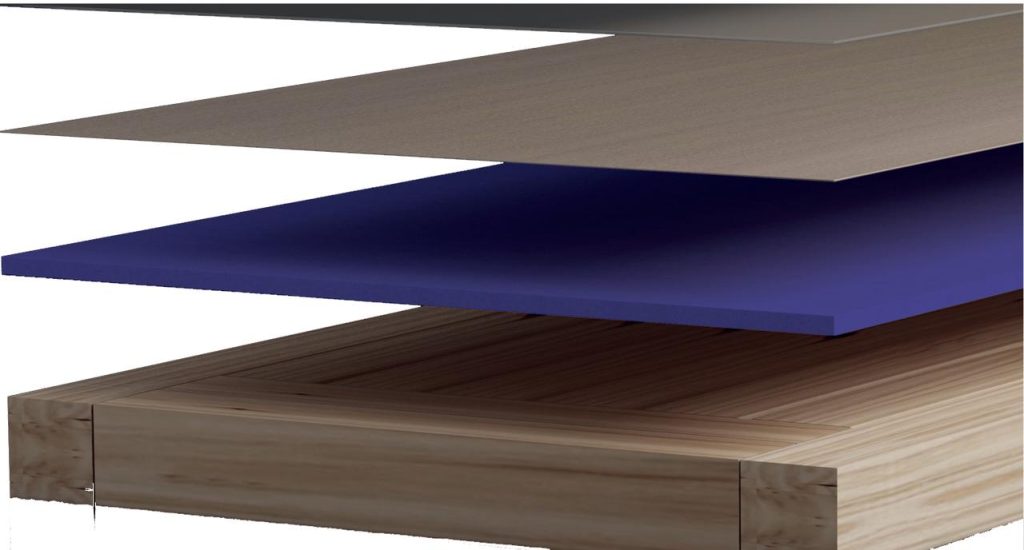

Section 1:Materials of Door Skin

Opanpan Carbon Fiber MDF Door Skin DFL-30P Series are made of carbon fiber MDF panel and melamine paper without painting process.

Carbon fiber MDF is rich in activated carbon negative ions.It can decompose formaldehyde produced during home decoration and absorb odors such as benzene and TVOC.At the same times ,it can release negatiive oxygen ions to purify the air.

MDF has a moderate density, which gives it good machining properties. At the same time, it can be glued and inlaid with various veneers, acrylic or metal sheets to meet different aesthetic needs.

The melamine paper is formed by three layers as:Top paper is the outermost protective layer, which makes the door skin hard, wear-resistant and highly transparent. Decorative paper is located under the top paper, which plays a decorative role and has good hiding power, impregnation and printing properties. Bottom paper is made of phenolic resin glue as a mechanical support to provide structural stability for the door skin.

- Adsorption

Nano-crystal micropores strongly adsorb formaldehyde, benzene, TVOC and other odorous or toxic gases.

- Decompostion

Nano-catalysis strongly decomposes the adsorbed formaldehyde and other harmful substances.

- Negative oxygen ions

Release negative oxygen ions in real time, truly achieving a three-layer purification effect.

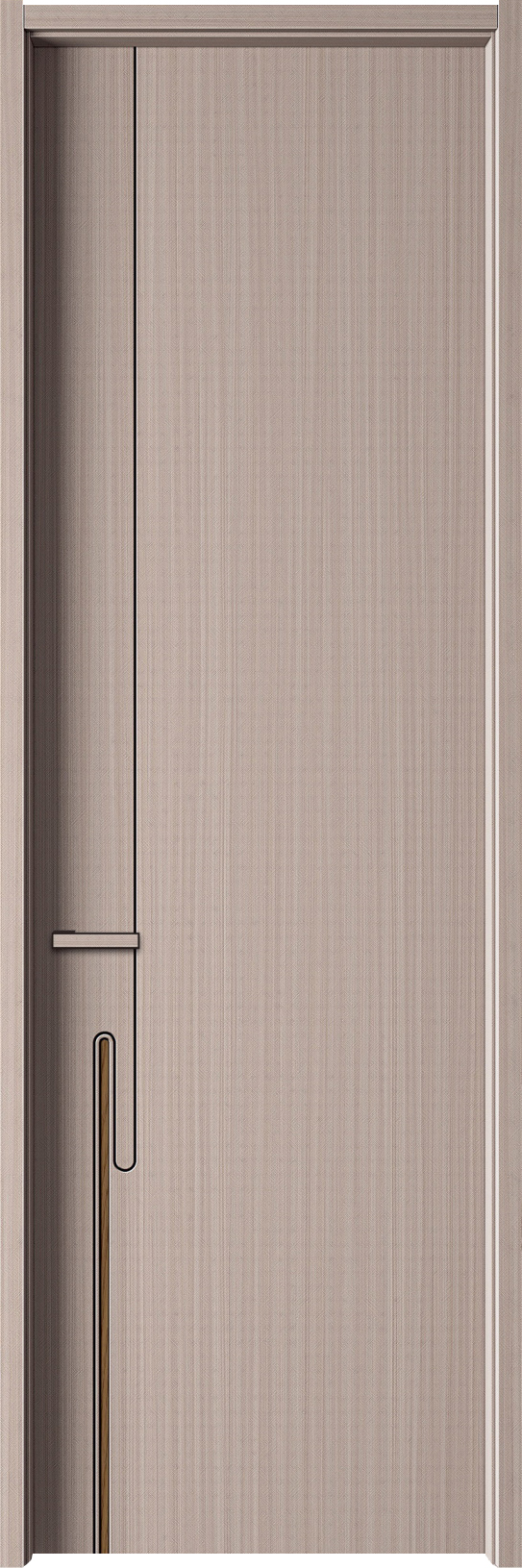

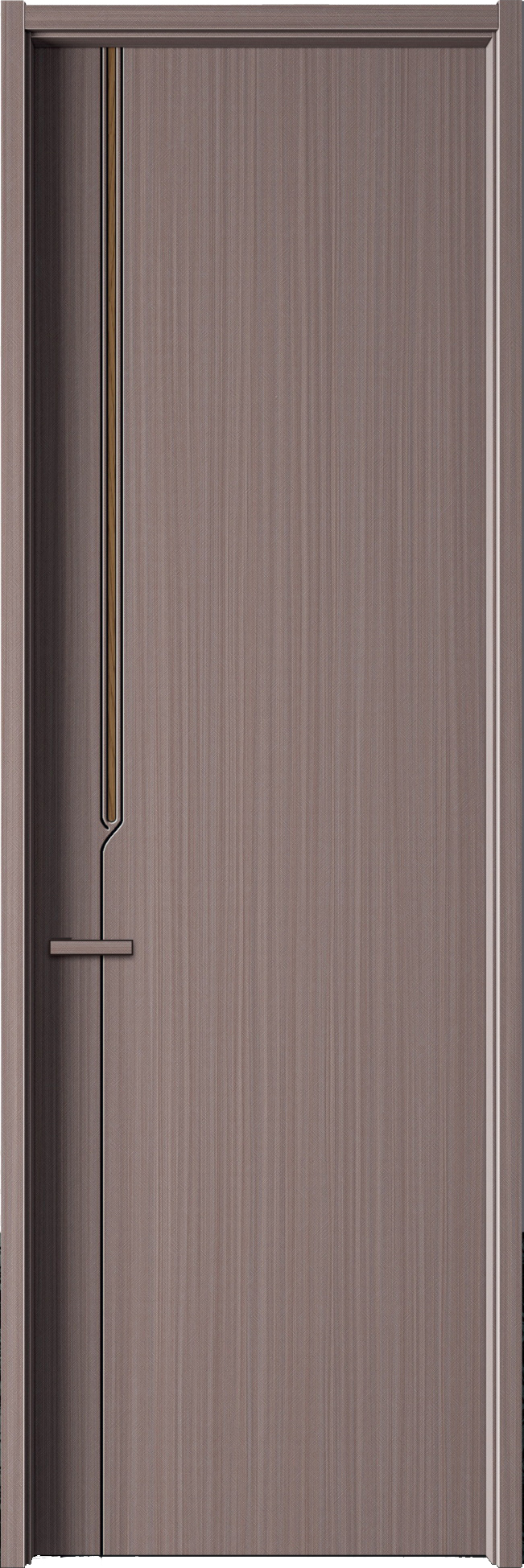

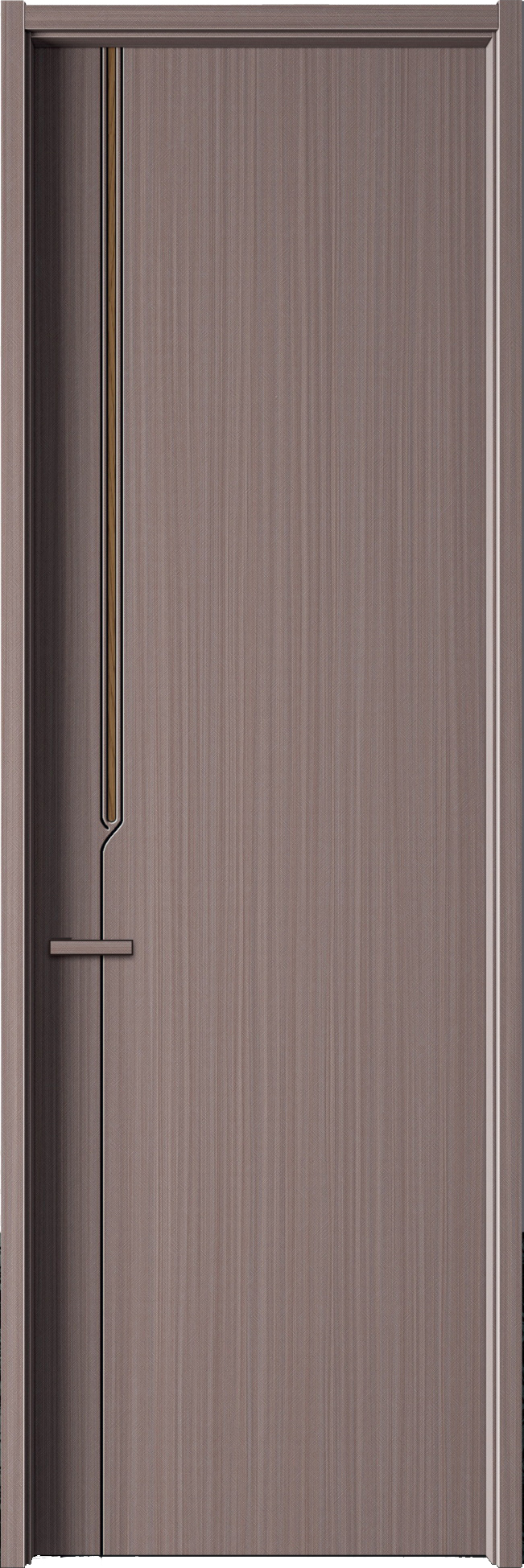

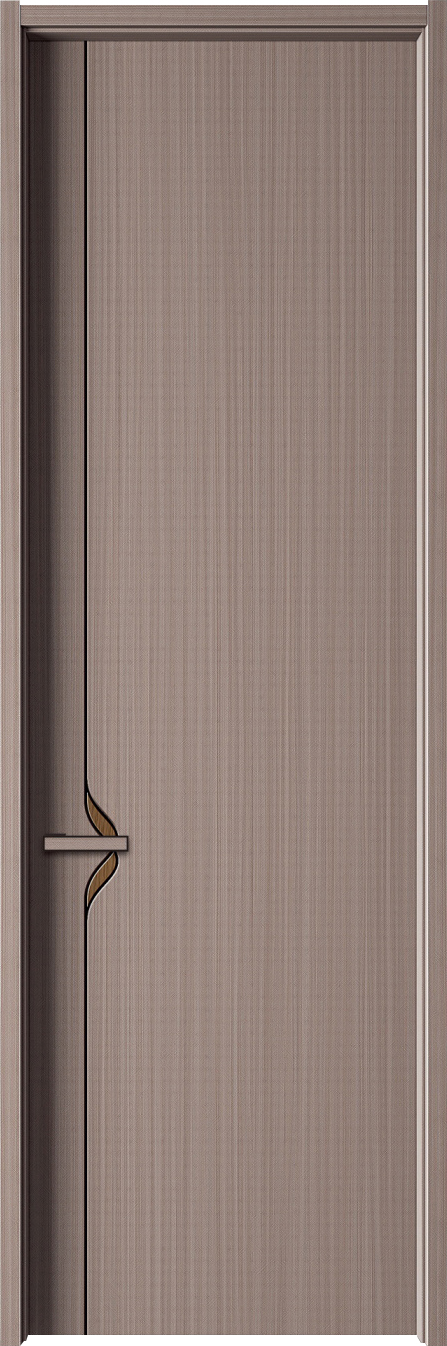

Section 2: Contemporary minimalist design of composite wooden doors

Within the maximum size limit, customers can freely customize the size of the door.Within simultaneous molding、carving and inlaying etc. processes, the door skins derives various designings and all of them can be customized according to customer requirements.

| Max size of customizatiion | Max size of customization |

| Thickness of door leaf | 45mm or Customization |

Section 3: Surface treatment

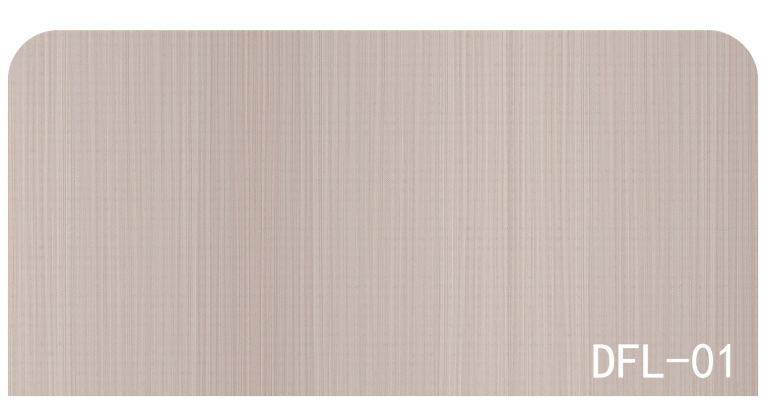

Section 4: Colour of surface

Door panel design is produced by the pattern of melamine paper, combined with molding, carving and inlaying etc. processes. The common patterns of melamine paper are as follows, and it can also be customized according to customer requirements.

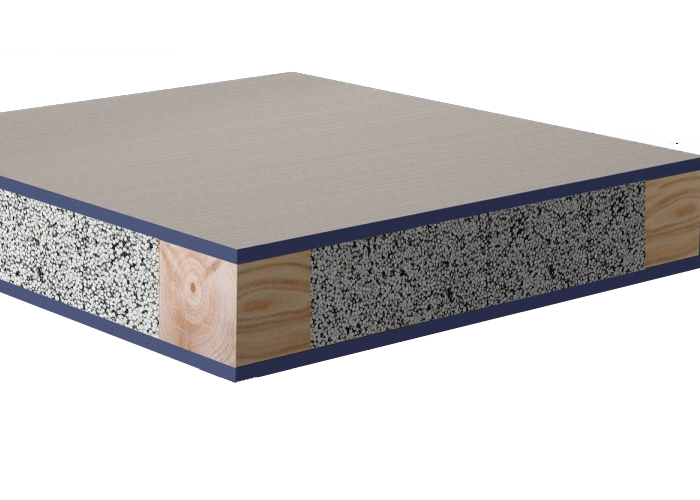

Section 5: Filling Materials of door

The filling materials in the door panels are mainly composed of solid wood, bridge hole boards, MDF, honeycomb paper and graphene,which can be mixed and matched. The above materials have different performances in terms of door panel strength, sound insulationand weight. Customers can customize according to their actual needs.

| Graphene | 3D Silent Mechanical Board | Bridge Hole Knot Board |

| Graphene has high strength | The three-dimensional silent | The bridge hole knot board has |

Section 6: Decoration scene

After the decorative panels and fillers are bonded, molded, cut, and edge-sealed, a relatively complete door leaf is formed. The door leaf has many excellent properties, such as environmentally friendly, formaldehyde-free, waterproof, soundproof, and scratch-resistant. Customers can freely customize various door locks and hinges installation on the completed door leaf.

* Conventionally, 5mm or 8mm MDF veneer as decoration door skin panel, and various shapes can be customized and carved.

* The four sides of the door leaf, the lock location and the internal frame structure are all made of multi-layer solid wood , which provides a thick and stable solid wood feel.

* Double-sided non-painting process, environmentally friendly, waterproof and wear-resistant.

* Various designs are available, which can be adapted to various architectural styles of different regions and cultures.

* The internal filling can be freely selected from solid wood square, bridge hole board, honeycomb paper, and graphene etc., with excellent noise reduction effect.

Section 7: About Opanpan

As a manufacturer, Linyi Oupanpan Door Industry Co., Ltd.(short for Opanpan) specializes in the R&D and production of decorative door skins, wall panels, molding lines and finished doors. The main type of decorative door skins is density board veneer melamine paper. It derives various decoration styles through molding , carving ,inlaying etc. processes. At the same time, Opanpan produces wall panels and molding lines in the same color as the door skin. It enables decoration service providers who cooperate with Opanpan to provide their customers with more design-oriented service solutions.

With the fact that finished door filling materials,such as brigde structure particleboard,graphene,honeycomb papaer ,are all under Opanpan Self-operated R&D and production, it prompts Opanpan master the core technologies in interior door key indicators as quietness, fire resistance and waterproofness etc.Opanpan is located in Linyi, China, which is known as the world’s board capital. Opanpan currently directly operates two production bases, one logistics storage center and an exhibition hall. The first production base is located at Cross of Industrial 2 road and Shengya Road and mainly produces decorative door skins, wall panels,molding lines and honeycomb paper. The production base covers an area of 45,000 square meters and has a variety of production equipment and processes, such as hot pressing production lines, carving production lines, and gluing production lines.

Production Strength

Opanpan is located in Linyi, the world’s capital of panels. It can provide high-quality and low-cost products to customers .

Advanced Equipment

Opanpan wooden door production line uses equipment produced in Germany. It has explored reliable production technologies.

Continuous innovation

Opanpan keeps a close eye on the international market, to meet the customers from different cultural backgrounds.

Safety performance

We realize that the door is part of the home, so from the beginning, we always put the safety of the product in an important position.

Professional R&D

Opanpan research and development is not limited to the style and appearance, but also goes deep into the field of raw materials.

Eeo- protection concept

We implement eco-protection concepts in raw material procuremen. We advocate the protection of scarce forest resources.

5-year warranty

We solemnly promise that within 5 years from the date of delivery of the product through reasonable channels and initiate a claim.

Worldwide delivery

Opanpan is only 3-hour drive from Qingdao Port. We can deliver the goods you need to you with the best transportation solution.

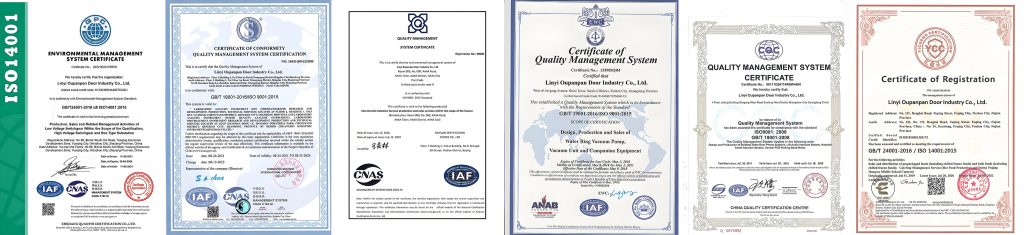

section 8 Certifications

Opanpan Door Skins

Opanpan Door Skins